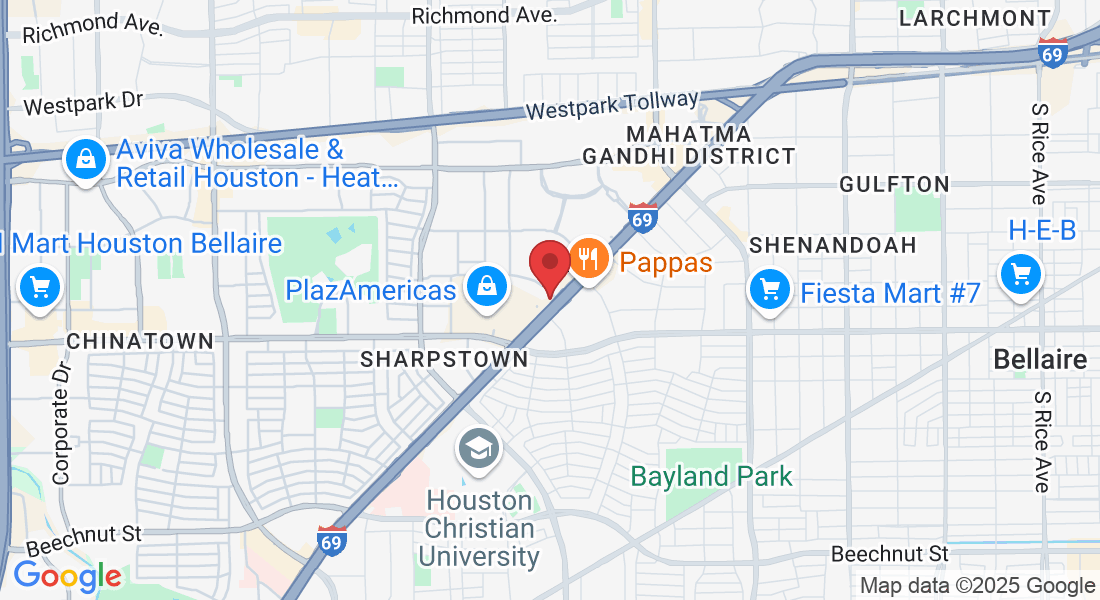

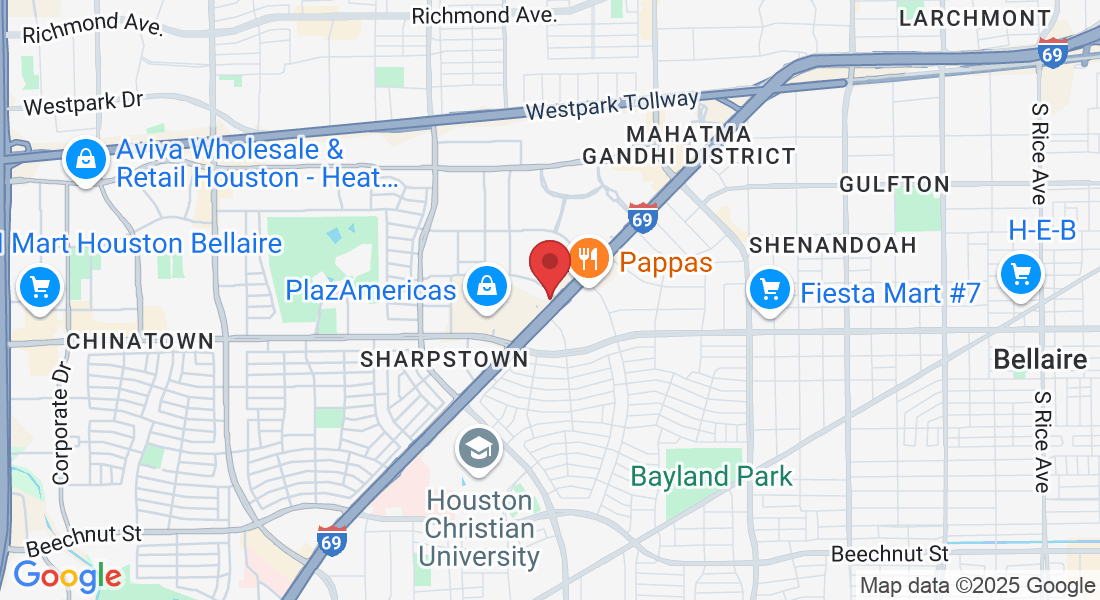

7070 Southwest Freeway

Houston Texas, 77074

Send your mail at

[email protected]

Working Hours

Mon – Sat 9:00am – 8:00pm

7070 Southwest Freeway

Houston Texas, 77074

Send your mail at

[email protected]

Working Hours

Mon – Sat 9:00am – 8:00pm

Call Us at

713-766-6471

Restore Your Rims to Perfection with Expert Cracked Rim Repair

Experience Unmatched Quality and Safety with Our Precision Welding and Finishing Services

SAFE REPAIR METHODS

We prioritize safety in every repair we perform. At 1 Day Wheel Repair, our eco-friendly methods ensure that your wheels are fixed without compromising the environment or your health. Our experts follow best practices to deliver repairs that not only restore functionality but also enhance your vehicle's safety and performance.

Trust us to handle your wheel repairs with care—contact us to book your appointment today!

PROFESSIONAL WHEEL REFINISHING

Enhance the look of your wheels with our expert refinishing services. At 1 Day Wheel Repair, we offer professional refinishing to restore your wheels to their original shine, improving both aesthetics and value. Our refinishing process eliminates scratches, curb rash, and other imperfections, giving your vehicle a fresh and polished appearance.

Let us help you bring your wheels back to life with a flawless finish. Contact us today for a transformation you’ll love!

Top-Quality Wheel Repair Get Your Wheels Restored Today!

Get Competitive Pricing and Exceptional Service!

Top-Quality Wheel Repair Get Your Wheels Restored Today!

Get Competitive Pricing and Exceptional Service!

WELCOME TO

1 DAY WHEEL REPAIR

Since its founding in 1996, 1 Day Wheel Repair has become the leading provider of custom and specialty finishes in the industry. With over 25 years in the vehicle and wheel business—under the same ownership—we have outpaced all competitors. We pioneered the modern innovations in Houston’s wheel and tire industry, introducing the "SAME DAY RIM REPAIR" service in the late 1990s.

Innovation is at the core of our business. Today, we proudly offer Powder Coating, an advanced technology that combines eco-friendly clean pre-treatment with enhanced application techniques and pulse power technology. We also utilize Fusion Coating, a patented process for superior results.

Revive Your Wheels with Expert

Cracked Wheel Repair

Cracked wheel repair involves fixing wheels damaged by cracks or impacts, such as those from potholes or curbs. Our repair process restores wheel integrity and performance for enhanced safety and longevity.

We start with a thorough inspection to identify visible and hidden damage using advanced diagnostic tools. The wheel is then cleaned and prepared for repair. Our technicians use TIG welding, employing a tungsten electrode to create an electric arc that melts and fuses the metal, reinforced with a filler rod of similar alloy to restore strength.

After welding, we smooth and finish the area to eliminate sharp edges or rough spots. The wheel is balanced and undergoes a rigorous quality check to meet high safety and performance standards. Trust our team to return your wheels to peak condition for a smooth, safe driving experience.

Why Cracked Rim Repair

Automobile wheels can crack for a variety of reasons. Impact damage from hitting a pothole or curb, overloading the vehicle beyond its recommended weight limit, and driving on rough or uneven terrain are common causes of wheel damage.

Additionally, wheels can become cracked over time due to wear and tear, especially if they are not properly maintained or if they are exposed to harsh environmental conditions

What We Do To Cracked Rim Repair

To achieve a high-quality and durable result, we follow these steps for every Cracked Rim Repair we perform for our customers.

The damaged wheel is first thoroughly cleaned and inspected to determine the extent of the damage. This includes checking for any hidden cracks or structural damage that may not be immediately visible.

The wheel is then prepped for repair by grinding down the cracked area to remove any damaged metal and create a clean surface for the welding process. This helps to ensure a strong and durable repair.

The alloy TIG welding process is then used to repair the crack. TIG welding involves using a tungsten electrode to create an electric arc that melts the metal and fuses it together. A filler rod made of a similar alloy is also used to fill in the cracked area and reinforce the repair.

The weld is carefully built up, layer by layer, until the crack is completely filled in and the wheel is restored to its original shape and strength.

Once the welding is complete, the wheel is smoothed and finished to ensure that there are no sharp edges or rough spots that could cause damage or affect the performance of the tire.

The repaired wheel is then balanced and reinstalled on the vehicle, and a final inspection is performed to ensure that the repair is secure and the wheel is safe to use.

What We Do To Cracked Rim Repair

To achieve a high-quality and durable result, we follow these steps for every Cracked Rim Repair we perform for our customers.

The damaged wheel is first thoroughly cleaned and inspected to determine the extent of the damage. This includes checking for any hidden cracks or structural damage that may not be immediately visible.

The wheel is then prepped for repair by grinding down the cracked area to remove any damaged metal and create a clean surface for the welding process. This helps to ensure a strong and durable repair.

The alloy TIG welding process is then used to repair the crack. TIG welding involves using a tungsten electrode to create an electric arc that melts the metal and fuses it together. A filler rod made of a similar alloy is also used to fill in the cracked area and reinforce the repair.

The weld is carefully built up, layer by layer, until the crack is completely filled in and the wheel is restored to its original shape and strength.

Once the welding is complete, the wheel is smoothed and finished to ensure that there are no sharp edges or rough spots that could cause damage or affect the performance of the tire.

The repaired wheel is then balanced and reinstalled on the vehicle, and a final inspection is performed to ensure that the repair is secure and the wheel is safe to use.

Overall, alloy TIG welding is a precise and effective method for repairing cracked wheels, and can restore damaged wheels to their original strength and integrity. With proper care and maintenance, a wheel that has been repaired with TIG welding can provide reliable and safe performance for many years to come.

SAFE REPAIR METHODS

We prioritize safety in every repair we perform. At 1 Day Wheel Repair, our eco-friendly methods ensure that your wheels are fixed without compromising the environment or your health. Our experts follow best practices to deliver repairs that not only restore functionality but also enhance your vehicle's safety and performance.

Trust us to handle your wheel repairs with care—contact us to book your appointment today!

PROFESSIONAL WHEEL REFINISHING

Enhance the look of your wheels with our expert refinishing services. At 1 Day Wheel Repair, we offer professional refinishing to restore your wheels to their original shine, improving both aesthetics and value. Our refinishing process eliminates scratches, curb rash, and other imperfections, giving your vehicle a fresh and polished appearance.

Let us help you bring your wheels back to life with a flawless finish. Contact us today for a transformation you’ll love!

Top-Quality Wheel Repair Get Your Wheels Restored Today!

Get Competitive Pricing and Exceptional Service!

Top-Quality Wheel Repair Get Your Wheels Restored Today!

Get Competitive Pricing and Exceptional Service!

OUR LATEST WORKS

Before

The repair process usually involves assessing the extent of the damage and determining the appropriate repair method. The repair process typically requires specialized tools and expertise, and should only be performed by a trained and experienced professional..

WHY 1DAY WHEEL REPAIR?

Expertise and Experience: Houston Wheel Repair has been in the wheel repair industry for several years, and their team of skilled technicians have the expertise and experience to handle a wide range of wheel repair issues, including repairing cracked wheels with alloy TIG welding.

State-of-the-art Equipment: Houston Wheel Repair uses the latest, state-of-the-art equipment and technology to ensure that every repair is done with precision and accuracy. They have invested in top-of-the-line welding equipment, which allows them to perform high-quality alloy TIG welding repairs that are both strong and durable.

Quality Materials: Houston Wheel Repair uses only the highest quality materials and alloys for their repairs, ensuring that the repaired wheels are as strong and durable as the original ones. They also offer a variety of custom finishes and colors to give your wheels a new look.

Fast and Convenient Service: Houston Wheel Repair offers fast and convenient service, with most repairs completed within a few hours. They also offer mobile repair services, where they can come to you and repair your wheels on-site, saving you time and hassle.

Competitive Pricing: Houston Wheel Repair offers competitive pricing for their services, making it an affordable option for those who need wheel repairs. They also provide a free estimate for their services, so you can know the cost upfront.

WHY 1DAY WHEEL REPAIR?

Expertise and Experience: Houston Wheel Repair has been in the wheel repair industry for several years, and their team of skilled technicians have the expertise and experience to handle a wide range of wheel repair issues, including repairing cracked wheels with alloy TIG welding.

State-of-the-art Equipment: Houston Wheel Repair uses the latest, state-of-the-art equipment and technology to ensure that every repair is done with precision and accuracy. They have invested in top-of-the-line welding equipment, which allows them to perform high-quality alloy TIG welding repairs that are both strong and durable.

Quality Materials: Houston Wheel Repair uses only the highest quality materials and alloys for their repairs, ensuring that the repaired wheels are as strong and durable as the original ones. They also offer a variety of custom finishes and colors to give your wheels a new look.

Fast and Convenient Service: Houston Wheel Repair offers fast and convenient service, with most repairs completed within a few hours. They also offer mobile repair services, where they can come to you and repair your wheels on-site, saving you time and hassle.

Competitive Pricing: Houston Wheel Repair offers competitive pricing for their services, making it an affordable option for those who need wheel repairs. They also provide a free estimate for their services, so you can know the cost upfront.

Experience Premium Car Repair Service—Check Out Our Top-Notch Solutions for Your Vehicle

Post Address and Mail

Email: [email protected]

Address

Office: 7070 Southwest Freeway

Houston Texas, 77074

Get In Touch

Assistance Hours

Mon – Sat 9:00am – 8:00pm

Sunday – CLOSED

Phone Number:

713-766-6471

Post Address and Mail

Email: [email protected]

Address

Office: 7070 Southwest Freeway

Houston Texas, 77074